Benefits of an Energy-Efficient Pole Barn

Internationally, code officials have recognized the need for a modern energy conservation code (ECC). This regulation addresses the design of energy-efficient building envelopes and related systems.

Some U.S. states have adopted ECC and require HVAC structures to be compliant. Please contact your city hall or county courthouse for minimum design and construction requirements. You may wish to follow these guidelines, even if it’s not required in your area.

Below, we discuss the two benefits of designing an energy-efficient pole barn.

Good for Your Budget

As the owner of a post frame structure, did you know that energy is the largest controllable operating expense?

Rising energy bills can be attributed to heating, cooling, and lighting resources.

Incorporating energy efficiency is your best hedge against escalating prices. It can minimize consumption and help you realize tangible savings.

Good for the People (and Animals) Using It

Energy efficiency isn’t just about saving money. In the end, it’s about making your pole barn a comfortable space to:

- Service heavy machinery

- Sell products or services to consumers

- Spend quality time with family and friends

- Board, groom, and ride horses

Your post frame building should meet your needs (and expectations). Monetary savings are a bonus.

Cost of an Energy-Efficient Pole Barn

Often, “expensive” is a term associated with “energy efficiency.” In our honest opinion, it boils down to perspective.

Generally, the more energy-efficient choices you make for your post frame structure, the higher the initial investment.

However, additional expenses can be offset by lower operating costs. To determine which upgrades will provide a good return, you’ll need to:

- Establish a baseline building

- Compare that to an upgraded building in terms of cost and performance

This cost versus value analysis may sound overwhelming. Knowledgeable Project Sales Consultants will be able to explain the variables and arrive at the best decision for you.

Understanding the Building Envelope & Heat Transfer

The building envelope (or shell) consists of materials that separate the outside from the inside. These components include the roof, attic, walls, foundation, doors, and windows.

So, how does it affect energy efficiency? The building envelope determines the amount of heating, cooling, and lighting resources a post frame structure will utilize.

Each component is a pathway for heat transfer. They work together to control the energy flow between the interior and exterior.

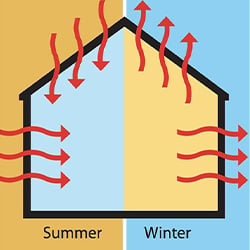

What is heat transfer? Naturally, thermal energy moves from warmer to cooler areas until the temperatures equalize. It travels in one of three ways, through:

- Conduction

- Convection

- Radiation

A well-designed building envelope will reduce all three types of heat transfer.

Conduction

First, conduction describes the heat flow within a solid material. You can reduce conduction heat loss by using building envelope materials with high R-values.

Convection

Second, convection is the process of transferring heat from one place to another through gas or liquid particles. This type of heat loss occurs when warm air escapes, and cold air enters. You can reduce convection by limiting the amount of air infiltration and exfiltration through the building envelope.

Radiation

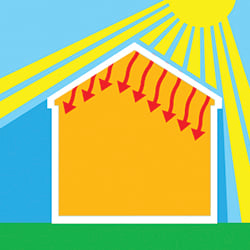

Third, radiation is heat transfer by electromagnetic waves from a warmer to a cooler surface. A prime example of radiation is the transfer of the sun’s heat to earth.

Moreover, the building envelope materials must be properly selected, designed, and installed. The basic objective is to minimize heat gain in the summer and heat loss in the winter.

The choices you make during the design phase of your pole barn will determine its energy efficiency for the foreseeable future. It’s crucial that you work with a post frame builder who can provide informed recommendations.

Importance of R-Value

In post frame construction, insulation is your primary defense against heat loss through the building envelope.

Although upfront costs may seem daunting, insulating your pole barn is an investment on its own. Your monthly operating costs will decrease considerably based on the insulation’s R-value.

What is an R-Value?

A rating known as an R-value measures insulation’s resistance to heat flow (or conduction). The higher the R-value, the higher the resistance to heat loss.

Furthermore, the amount of R-value your post frame building will require depends on the following factors:

- Climate zone

- Type of heating and cooling system installed

- Size of the area needing an extra layer of defense

While it’s a useful measure, the R-value is only one way to gauge the effectiveness of insulation. Air infiltration and other factors must be taken into account.

For example, a pole barn with high R-value insulation (but lots of air leaks) may be colder in the winter than an airtight building with low R-value material. Therefore, the entire “system” must be considered.

Keep in mind, the overall R-value of a wall or ceiling may differ from that of the insulation itself. Sometimes, heat flows around the padding and through laminated posts or Perma-Columns.

Working with a professional builder will ensure proper installation; thus, achieving the maximum R-value.

4 Types of Pole Barn Insulation

Now that you understand the importance of R-value, we can discuss the different insulating materials for your post frame building.

Now that you understand the importance of R-value, we can discuss the different insulating materials for your post frame building.

When considering your heating options, ask yourself the following questions:

- Will the structure be heated?

- How will you keep it warm?

- Will it be permanently or temporarily heated?

- When you look up, will you see trusses or a finished ceiling?

Your answers will guide you through the decision-making process.

1) Perimeter Slab Insulation

If you walk outside to your garage, chances are it has a concrete slab floor sitting on top of the ground. The ground has its own R-value. So, if you insulate the perimeter, you can protect that rating and prevent heat from escaping around the building.

Typically, a solid two-inch piece of rigid board insulation is installed vertically alongside the columns, or horizontally under the floor.

Does your pole barn have in-floor heating? Or maybe it sits over a high-water table? If so, you’ll want to insulate under the entire floor. Otherwise, the water will steal the heat as it flows away from your structure.

2) Wall Insulation

The exterior walls of your pole barn act as a barrier from the harsh winter weather. Without wall insulation, conduction will occur regardless of the heating-cooling system you’ve employed. That’s a waste of your hard-earned money!

For instance, heat will exit your tool shed even if the furnace is running full steam ahead. Therefore, adding insulation will significantly reduce heat conduction.

There are five types of wall insulation used in post frame buildings:

i) Fiberglass Batts

First, fiberglass batts are the most common wall insulation. It’s well-known for its relatively low cost and ease of installation.

Long spans of fiberglass insulation can be placed in-between posts, resulting in fewer breaks (air leaks) between the batts.

If you choose fiberglass batts, you’ll want to look into purchasing a vapor barrier. It’s an impermeable material placed in-between the interior wall and insulation.

Vapor barriers minimize condensation caused by moisture buildup within the envelope. This layer prevents insulation from getting wet, which lessens its performance and contributes to its deterioration.

Installed price ranges from $0.95 to $1.30 per square foot of wall.

ii) Vinyl Back

On the other hand, vinyl back is a fiberglass batt with a white coating on the backside. Usually, it’s fitted in-between framing, but that can cause issues with sagging. Vinyl back is a thinner insulation than fiberglass batts, making it a lower R-value.

Not to mention, it can be a challenge to situate properly. The R-value varies by thickness.

Installed price ranges from $1.90 to $4.00 per square foot of wall.

iii) Sprayed Polyurethane Foam (SPF)

In recent years, sprayed polyurethane foam (SPF) has become a popular but more expensive alternative to fiberglass batts. SPF fills and seals all exposed areas and cracks within the structure, giving you greater protection from air drafts and moisture.

Due to the chemicals and equipment involved, a professional spray-foam contractor should be hired for the job.

However, if your wall needs to be replaced, this material can be difficult to remove due to its glue-like characteristics. That's why we recommend having building wrap (e.g., Tyvek®) installed on your steel before adding spray foam.

Additionally, some spray foam products haven’t been tested for steel use. In fact, cellulose insulation can cause steel corrosion due to its ingredients (e.g., fire retardant chemicals).

Consequently, some metal suppliers won’t provide warranty coverage if SPF is used. Don’t forget to check with your pole barn builder before making a final decision.

Installed price ranges from $3.50 to $5.50 per square foot of wall.

iv) Rigid Board Insulation

Placed directly underneath the exterior steel siding, these rigid panels of insulation provide a very high R-value with continuous coverage. As a result, there is less air infiltration.

Most importantly, not all rigid board products are created equal. Please make sure it’s approved for use in exposed applications.

Installed price ranges from $2.10 to $3.30 per square foot of wall.

v) Building Wrap

Technically, building wrap isn’t a type of insulation. Instead, it’s an optional convection barrier that’s positioned underneath your structure’s steel siding.

Building wrap is an additional moisture and air infiltration blockade. It works together with your pole barn insulation for a comfortable interior.

Before purchasing, you should research building codes, steel strength, and insulation options. These considerations will help determine if building wrap is a wise investment for you.

Again, you can contact your city hall or county courthouse for local building codes.

Installed price ranges from $0.25 to $0.35 per square foot of wall.

Which Wall Insulation Do We Recommend?

Altogether, fiberglass batts and spray foam are the best insulating materials for your post frame building.

Fiberglass batts are a cost-effective solution that works uniquely with pole barn columns.

Spray foam insulation provides superior R-value and airtightness. The higher cost and laborious installation are a couple of drawbacks.

3) Attic Insulation

This requires a steel or drywall ceiling to be installed first. Once finished, the most common attic insulation options are fiberglass batts and blown insulation.

When blown insulation is installed correctly, the loose-fill provides an airtight finish between the ceiling joists and bottom chords of the trusses.

A contractor with specialized equipment applies blown insulation. It’s easy to insert (no cutting or fitting), can adapt to any R-value, and conform to odd-shaped spaces.

According to the Energy Star®, the recommended level is R-38 (10 to 14 inches) for attics.

Installed price ranges from $0.95 to $1.25 per square foot of ceiling.

Which Attic Insulation Do We Recommend?

Overall, we recommend blown insulation for your attic. Keep in mind that loose-fill material requires a ceiling. If you don’t plan on building a ceiling, then you’ll need roof insulation.

4) Roof Insulation

Lastly, an insulated roof is an inexpensive substitute for interior liner packages with attic insulation. Typically, it’s placed under the roof sheathing, exposing truss members.

This type of insulating material works well with radiant heat as opposed to forced air. With the latter, much of your heat rises into the truss space.

As mentioned above, rigid board insulation is a typical roof application. It prevents the need for other finishing touches (e.g., drywall). The foil layer will reflect radiation, which will keep the building cooler in the summer. It has a white surface, which brightens the interior and lowers lighting resources.

In addition, a radiant barrier (the combination of batts and spray foam insulation) reduces energy by absorbing and slowing heat transfer. Then, it plugs any air leaks (convection).

Radiant barriers can be placed anywhere in your post frame building. But, it works better in attics or under roofs of air-conditioned structures. Please keep in mind that a radiant barrier only functions when at least one side is facing an air space.

Which Roof Insulation Do We Recommend?

Another roofing option we recommend is spray foam insulation albeit its cost.

Why Door & Window Placement Matters

Doors and windows not only create views but admit solar energy and supply natural ventilation. The form, size, and location of these openings depend on the building envelope.

A great deal of heat loss will occur around these building components. Therefore, selecting the right quality (and quantity) of doors and windows will be a major decision.

Energy-efficient choices will lower your pole barn’s heating, cooling, and lighting costs. Be sure to hire a contractor who makes precise installation a priority.

What Should You Look for in Doors?

What Should You Look for in Doors?

The primary source of door-related heat loss is due to poor sizing and weatherstripping. Plus, the constant opening and closing for building access.

Ideally, you should select doors with built-in thermal breaks that separate interior and exterior surfaces. This core material cuts heat loss in the winter and heat gain in the summer.

Without an excellent thermal break and weather seal, the promoted R-value of the door is worthless.

For large entry doors, we recommend a door type that allows easy access and provides an airtight perimeter seal.

What Should You Look for in Windows?

All windows have a National Fenestration Rating Council (NFRC) rating in the following areas:

- U-Factor: Determines how well a product prevents heat from escaping. A lower U-factor has better insulating power.

- Solar Heat Gain Coefficient (SHGC): Measures how well a product blocks heat caused by sunlight. A lower SHGC score means less solar heat transmitted into the structure.

- Visible Transmittance (VT): Grades how well a product is designed to light your structure with daylight, resulting in energy savings. A higher VT number lets in more natural light.

- Air Leakage (AL): A lower air leakage rating indicates superior building airtightness.

- Condensation Resistance (CR): Ranks the product’s ability to withstand condensation on the interior surface. The higher the CR grade, the better resistance to moisture buildup. This label is optional for window manufacturers.

High-quality framing materials such as wood, vinyl, and aluminum reduce heat transfer and precipitation.

Pole barn windows with multiple panes insulate much better than a single sheet of glass. Some energy-efficient windows have an inert gas (e.g., argon and krypton) between the panes. These clear, non-toxic, odorless gases minimize conductive heat transmission.

On top of that, you should purchase windows with box trim. They have a rubber gasket and can be sealed to the steel siding via caulking. With J-channel, there is a slight gap between the channel and metal.

Other Heating Systems to Consider

Now that you understand the building envelope and its components, we can discuss the best ways to heat your pole barn.

Before we begin, it’s important to note that some utility companies offer rebates for using high-efficiency systems. Please check with your local energy provider for details.

Furnaces

Furnaces create heat by burning fuel, usually natural gas or propane. Commonly used in homes, furnaces can be used in post frame buildings and furnished interiors.

Remember, furnaces require a forced air distribution system involving ductwork. Units can be hung from the ceiling in areas where aesthetics aren’t critical (e.g., farm shops and hobby barns).

New furnaces are measured by the Annual Fuel Utilization Efficiency (AFUE). For example, gas furnace models range from 78% to 96% efficiency.

Heat Pumps

A heat pump is an electric all-in-one heating and cooling system that works year-round. Its purpose is to transfer heat from one place to another.

During the winter, a heat pump extracts heat from an outside source and transfers the energy indoors. In the summer, the heat flow direction is reversed to provide air conditioning.

The most common type of heat pump is the air-source heat pump. It moves heat between your building and the outside air. Higher efficiencies are achieved with geothermal (ground- or water-source) heat pumps. They transfer heat, as the name implies, between your building and the ground or a nearby water source.

Heat pumps are rated by their Heating Seasonal Performance Factor (HSPF).

Although heat pumps are incredibly efficient, they differ from conventional systems in the following ways:

- Have a higher initial cost

- Take longer to warm up or cool down a space

- Require a higher volume of air for movement

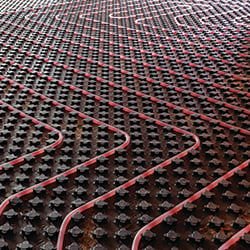

Radiant Heating Systems

A radiant heating system involves supplying heat directly from the ceiling or floor of a pole barn. This option is usually more effective than forced-air heating because no energy is lost through the ductwork.

However, if you want cooling, you’ll need separate ductwork installed for the A/C.

Radiant heat works by warming objects (and occupants) directly, instead of warming the surrounding air. Therefore, it’s highly recommended for post frame buildings with frequently opened doors.

There are two different types of radiant heating systems:

i) Surface-Mounted Radiant Ceiling Panels

Surface-mounted radiant ceiling panels can provide heat to the entire structure or certain zones. These panels can rapidly change a room's environment by heating and cooling when turned on and off, respectively.

ii) Radiant Floor Heating System

A radiant floor heating system is more expensive than its ceiling counterpart. It usually transmits heat with water. This option takes considerable time to heat but retains its warmth for a long time.

Stoves

Alternatively, stoves range from traditional wood-burning units to those that burn corn, oil, or sawdust pellets. They can be installed inside or outside your post frame building. A reputable dealer will explain the different stove features and sizes.

You can use a stove as your only heat source or a complement to the forced-air heating system.

Before you purchase a stove, you should consider the following factors:

- The need to buy and store fuel

- The time and effort required to tend the fire

- The possibility of emitting air pollutants that wouldn’t happen with a furnace or heat pump

Do your local building codes allow wood-burning appliances? It’s important to double-check before buying one.

Why? Because there’s always the risk of a fire outbreak. We’d hate to see your new post frame structure go up in flames.

Overall, our recommendation is to make sure you find Energy Star® products. The savings will benefit you in the long run.

Fun Fact: You can receive a tax credit by purchasing Energy Star® heating and cooling systems. Ask your accountant for more information.

Which Insulating Material & Heating System is Right for You?

Ultimately, how you choose to insulate your pole barn is up to you. Our goal as one of the top post frame builders in the Midwest is to recommend heating solutions that’ll help you get the most out of your space.

The price may seem intimidating. But remember, you only need to insulate parts of the structure that are climate-controlled. Well-insulated spaces will lower heat conduction, maximize comfort, and minimize fuel bills.

If you’re interested in purchasing an interior liner package or further exploring insulation options for your next post frame project, please give us a call at (800) 552-2981.