Building Construction | Financing

The Facts on Pole Barn Construction

Meet FBi's Marketing Content Creator, Julie. With a design degree from Purdue, she develops our brand, captures stunning building photos, and crafts informative brochures.

When comparing your post-frame building options, it always helps to start with the facts. Knowing the facts will give you better insight and confidence in your decision-making process.

In this article, we keep it real! Our goal is to hit you with the facts regarding pole barn construction. We will cover:

- History of pole barn buildings

- Pros and cons of building a pole barn

- Financial expectations

- Technology used to increase safety and building longevity

History of Pole Barn Buildings

THE BEGINNING - In the early 1930s, the Great Depression made it necessary to build with fewer materials. Being forced to think outside the box, inventor H. Howard Doane had the idea to combine utility poles and sheet metal which led to the creation of the first pole barn concept.

Little did he know he would start an economic movement that would grow and expand over the next 100 years.

THE MIDDLE - The agriculture industry took advantage of this pole barn concept and used it as affordable storage for farming equipment and livestock protection. This trend caught on and spread quickly throughout the country.

THE NOW - Pole building construction has turned into a “post frame” world. Countless ways to utilize this construction method, including commercial, residential, equine, and farm properties.

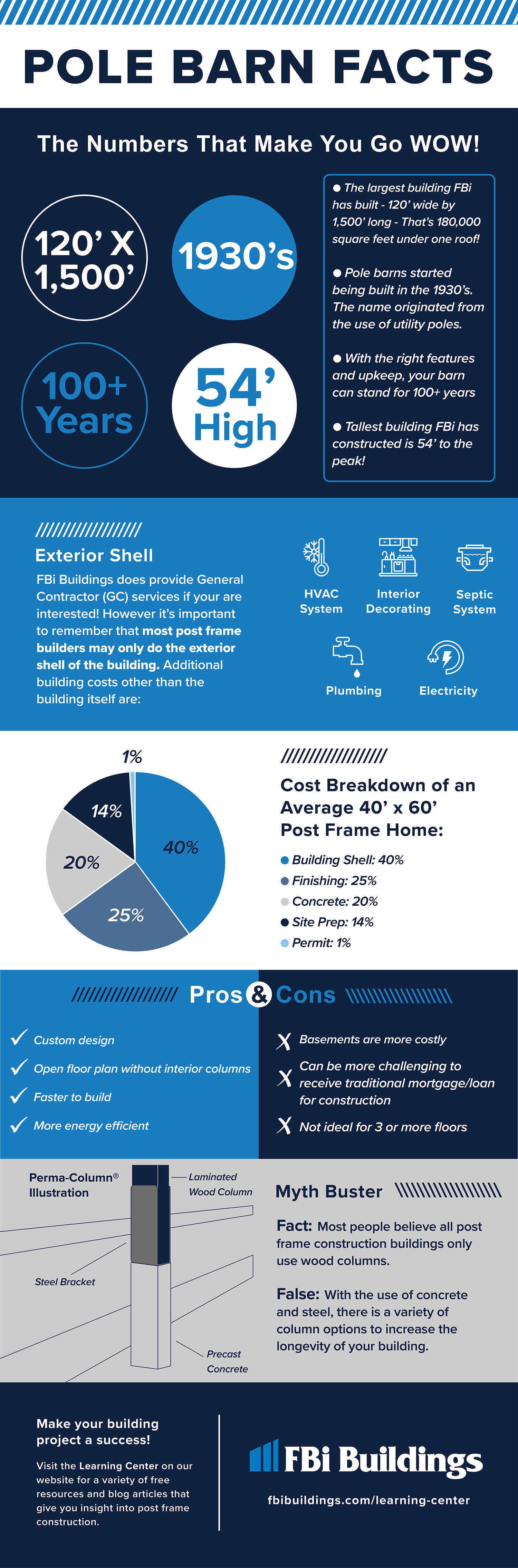

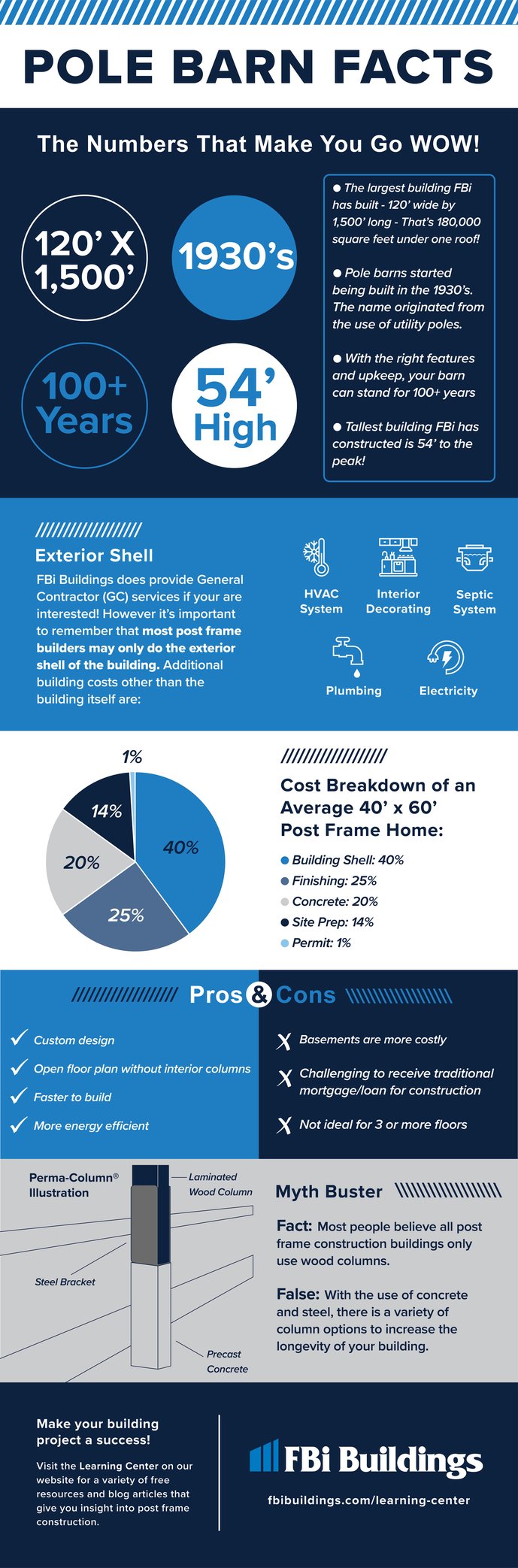

Impressive FBi Buildings stats that will make you go WOW:

- The largest building FBi has built is 120 feet wide by 1,500 feet long. That’s 180,000 square feet under one roof!

- The tallest building FBi has constructed is 54 feet high to the peak! The highest ceiling we’ve done is 35 feet.

Pros and Cons of Post-Frame Construction

PROS - It’s no secret that the popularity of post-frame construction is on the rise! From a barndominium to a shouse, we have the capabilities to build your dream home.

Here are a few key reasons why people love them so much:

- Custom design

- Open floor plan without interior poles

- Faster to build

- More energy efficient

CONS - If we lived in a perfect world, there wouldn’t be any cons. However, we like to keep it real and feel it’s right to keep you informed on the details that might impact your decision-making process.

A few post-frame construction challenges to keep in mind are:

- Basements are more costly

- Not ideal for 3 or more floors

- Can be more challenging to receive traditional mortgage/loan for construction

Financial Expectations

One of the most crucial factors during the construction process is staying on budget.

Here is the cost breakdown of an average 40’ x 60’ (2,400 square foot) post-frame home to help you budget accordingly:

- Building shell: 40%

- Finishing: 25%

- Concrete: 20%

- Site prep: 14%

- Permits: 1%

Notice we said, “building shell” - It’s imperative to remember that most post-frame builders will only erect the exterior shell of your building. Therefore, additional building costs other than the building itself are:

- HVAC System

- Septic System

- Plumbing

- Electricity

- Interior decorating and fixtures (floors, cabinets, lights, etc.)

To dive deeper into what your cost will look like, check out our article on Home Much Does a Pole Barn House Cost?

FBi Buildings offers General Contractor (GC) services if you are interested. In addition, we can assist you with building permits, have an excavator handle all the site prep, and ensure your project is scheduled to meet your deadline.

If you choose to be your own GC, this General Contracting guide will be a great resource to help you get started.

Technology Used to Increase Construction Safety and Post-Frame Longevity

As a leader in the post-frame construction world, FBi Buildings is constantly looking for ways to be innovative and efficient and raise the quality bar.

This forward-thinking mentality led to the creation of FBi Buildings’ QLYFT system. Building your project with QLYFT will ensure quality, enhance safety, and reduce delays in the construction schedule. The 6 key benefits of the QLYFT building system are:

- Enhanced quality control

- Transparent inspection

- Less strain on building materials

- Fewer delays due to weather

- Improved safety

- Reduced power line costs and delays

Fascinated and ready to learn more about our QLFYT system? Check out QYLFT Building System: Transforming Post Frame Construction.

FACT: Most people believe that all post-frame construction buildings only use wood columns.

THE TRUTH: With the use of concrete and steel, there are various column options to increase the longevity of your building.

To ensure that you get the most ROI for our post-frame facility, your post-frame builder must utilize the following:

- Perma-Columns®

- Kynar 500® paint

- Rust-free, stainless-steel hex washer head screws

- Light, aluminum-framed sliding doors with StepSaver Latch

This Structural Integrity eBook will give you the confidence that incorporating these new innovative building methods will ensure your building will stand for the next 50+ years.

Make Your Post Frame Building Project A Success

A new post-frame building is a large investment of your time and money. Visit the Learning Center on our website for various free resources and blog articles that give you insight into post-frame construction.

Now that you’ve done your research, reviewed the pole barn facts, and have your budget in mind, let us know, and we will provide you with a free quote!